Information contained in this news release is current as of the date of the press announcement, but may be subject to change without prior notice.

March 28, 2013

Hitachi Plant Technologies Received Order from India’s National Thermal Power Corporation for Large-scale Modification of Electrostatic Precipitators for Coal-fired Power Station

India Places Its First Order for our Original Moving Electrode Electrostatic Precipitators(”MEEP”)

Tokyo, March 28th, 2013—Hitachi Plant Technologies, Ltd. (“Hitachi Plant Technologies”) received an order from the National Thermal Power Corporation (“NTPC”) of the Republic of India (“India”) for the large-scale modification of electrostatic precipitators (total of two), one each on two 500 MW boilers of the Rihand Super Thermal Power Station in the state of Uttar Pradesh, India. Completion is scheduled for February 2016. This is the first order for moving electrode electrostatic precipitators (“MEEP”*) received by Hitachi Plant Technologies from India.

This order involves six-section type (configured of electrostatic precipitators in six sections) fixed electrode electrostatic precipitators that have been in use for approximately 25 years. The inside of the front four sections will be renovated into fixed electrode electrostatic precipitators and the rear two sections will be reconstructed as MEEP using Hitachi Plant Technologies’ original technology. Hitachi Plant Technologies will be in charge of planning, design, production, installation and test operation of all equipment.

This order is due to the features of high performance, space saving and the ability to collect high-resistivity dust of MEEP, which incorporate original technologies of Hitachi Plant Technologies, and the high assessment of cost competitiveness. This adoption of MEEP is expected to fully clear the required outlet dust concentration value of 50 mg/m3 N from the existing boilers and have the highest level of performance of any electrostatic precipitator operating in India.

In India, demand for electric power is increasing due to rapid economic growth. Between the present and 2017, the capacity of power generating facilities is projected to grow to 330 GW, double the current level. Above all, coal-fired thermal power plants currently account for about two-thirds of total power generating capacity in India and are expected to be the key source of electricity in the future. The strengthening of regulations covering the emission of dust from coal-fired power plants is anticipated; thus demand for electrostatic precipitators is projected to increase.

With this order as a foothold, Hitachi Plant Technologies will expand sales of electrostatic precipitators mainly to the emerging countries, including India, with moving electrode electrostatic precipitators and their distinctive features as a key technology.

* MEEP is a registered trademark of Hitachi Plant Technologies, Ltd. in Japan, India and other countries.

Outline of Order

| Power plant name | Rihand Super Thermal Power Station |

|---|---|

| Location | India, Uttar Pradesh, Sonbhadra district |

| Customer | National Thermal Power Corporation (NTPC) |

| Scope | Planning, design, production, installation and test operation of electrostatic precipitators (total of two), one each on two 500 MW boilers |

| Date of order | March 2013 |

| Scheduled date for start of construction | May 2014 |

| Scheduled date of completion | February 2016 |

Outline of Moving Electrode Electrostatic Precipitators (MEEP)

The electrical resistivity of dust greatly affects the performance of electrostatic precipitators. In particular, when high-resistivity dust (1011 W-cm or greater) is collected by a conventional fixed electrode electrostatic precipitator, the surface of the collecting plate becomes covered by layers of adhered dust. If operation continues under these conditions, high-resistance obstruction and the back corona phenomenon will occur due to the dust covering the collecting plate. The corona current from the discharge electrode will be abated, and the dust deposited on the collecting electrode will cause dielectric breakdown, seriously degrading dust collection performance.

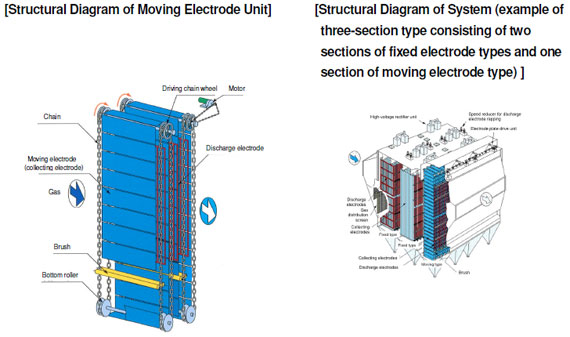

For the moving electrode electrostatic precipitator, a moving electrode mechanism and a new method that removes dust by means of brushes were developed, enabling the collection of high-resistivity dust by a dry apparatus and a space-saving footprint thanks to the system’s high performance.

About Hitachi Plant Technologies, Ltd.

Hitachi Plant Technologies, Ltd. – Supporting Infrastructure with Environmental and Energy-Saving Technologies – is a member of the Hitachi Group. Harnessing its engineering capabilities, Monozukuri (manufacturing) skills and project expertise, Hitachi Plant Technologies offers total solutions for social and industrial infrastructures. The core businesses of our group mainly comprise Social Infrastructure Systems (pumps, compressors and water treatment systems), Industrial Systems (mechatronics, and chemical and pharmaceutical plants), Air Conditioning Systems (industrial and building facilities) and Energy Systems (nuclear and thermal power plants construction, electrostatic precipitators and fabric filters). Hitachi Plant Technologies, Ltd. will merge with Hitachi, Ltd. on April 1, 2013 in order to strengthen its social innovation business.